Three Core Areas of Strategic Management

Strategic management is the process of formulating and implementing strategies that help organizations achieve their goals and objectives. The three core areas of strategic management are:

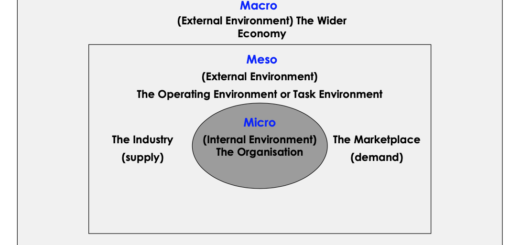

- Strategic Analysis: This is the first and most important stage of strategic management. It involves analyzing the internal and external environment of the organization to identify its strengths, weaknesses, opportunities, and threats. This analysis provides a basis for formulating strategies that can help the organization take advantage of its strengths, minimize its weaknesses, and exploit opportunities while managing threats.

- Strategy Formulation: This involves developing strategies that align with the organization’s mission, vision, and goals. The strategies are based on the results of the strategic analysis and take into account the resources, capabilities, and competencies of the organization. The strategy formulation process involves making choices about the direction and scope of the organization’s activities, the industries and markets it will serve, and the resources it will allocate to achieve its objectives.

- Strategy Implementation: Once the strategies have been developed, they need to be implemented effectively. This involves putting the plans into action by allocating resources, establishing policies and procedures, creating an organizational structure, and implementing programs and initiatives that support the strategies. Successful implementation requires effective leadership, communication, and monitoring to ensure that the organization is moving in the right direction and achieving its objectives.

Watch YouTube Short

Rotor Balancing with Balanset-1A: Advanced Vibration Analysis Methods for Industrial Equipment

In the realm of industrial machinery, ensuring the smooth operation of rotating equipment is paramount. Unbalanced rotors can lead to excessive vibrations, reducing efficiency and escalating maintenance costs. The Balanset-1A by Vibromera stands out as a cutting-edge solution, leveraging sophisticated vibration analysis methods for industrial equipment to deliver precise rotor balancing.

Overview of Balanset-1A

The Balanset-1A is a two-channel device designed for comprehensive balancing and vibration analysis. It is suitable for a wide range of rotors, including crushers, fans, mulchers, choppers on combine harvesters, shafts, centrifuges, and turbines. Priced at €1751, it offers both single and two-plane balancing corrections, adaptable to various rotor types and industrial applications.

The Balancing Process Using Balanset-1A

Balancing a rotor with the Balanset-1A involves several key steps, from equipment preparation to the final verification of balance.

1. Preparation of Equipment

Begin by installing vibration sensors perpendicular to the rotor’s axis of rotation. Secure the laser tachometer on a magnetic stand, directing it at a reflective tape attached to the pulley. Connect the sensors to the Balanset-1A unit and link the device to a laptop via USB. Launch the Balanset software, selecting the two-plane balancing mode to initiate the process.

2. Initial Vibration Measurement

Before balancing, weigh a test mass and record its weight and installation radius. Start the rotor and measure the initial vibration levels to determine the amplitude and phase of the existing imbalance.

3. Balancing in the First Plane

Place the test mass in the first balancing plane corresponding to the first sensor’s position. Run the rotor again to measure the vibration level. A change of at least 20% in amplitude or phase indicates partial correction of the imbalance.

4. Balancing in the Second Plane

Move the test mass to the second balancing plane (aligned with the second sensor) and re-run the rotor. These measurements allow the software to calculate the precise placement and weight of the corrective masses.

5. Correction of Imbalance

Based on the data collected, the Balanset program recommends specific corrective weights and their installation angles for both planes. Remove the test mass, prepare the corrective weights as per the software’s guidelines, and install them at the calculated angles in the rotor’s rotation direction.

6. Verification and Completion

Initiate a final rotor run to verify the balance. If vibration levels are within acceptable limits, the process is complete. Otherwise, the program will guide additional corrections to achieve optimal balance.

Features of Balanset-1A

The Balanset-1A is equipped with a range of features that enhance its functionality and ease of use:

Vibrometer Mode: Accurate measurement of rotational speed, phase angles, fundamental frequency, FFT spectrum, and overall vibration levels.

Balancing Mode: Supports both single-plane and two-plane balancing with visualization through polar graphs.

Charting and Reporting: Provides overall, 1x, harmonic, and spectrum charts for in-depth analysis, along with detailed reports and session archiving.

Additional Capabilities: Includes a tolerance calculator based on ISO 1940, grinding wheel balancing functionalities, and support for both Imperial and Metric systems.

Applications and Types of Rotors

The Balanset-1A caters to various rotor types, determining the balancing approach based on structural characteristics. Single-plane (static) balancing is ideal for narrow, disc-shaped rotors like grinding wheels, belt pulleys, and clamps. Two-plane (dynamic) balancing is suited for longer, multi-bearing rotors such as motors, compressors, and turbines.

Conclusion: Enhancing Industrial Efficiency with Balanset-1A

Implementing vibration analysis methods for industrial equipment is crucial for maintaining machinery performance and longevity. The Balanset-1A offers a reliable, precise, and user-friendly solution for rotor balancing, ensuring reduced vibrations, minimal wear, and optimized operational efficiency. Invest in Balanset-1A to safeguard your industrial equipment and achieve unparalleled balancing accuracy.

Contact Information:

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on Machinio

Balanset-1A OEM on Facebook Marketplace